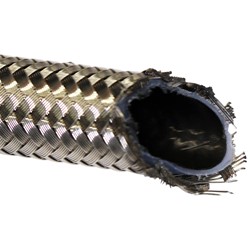

TFT1167-03B - Teflon SS Braided Hose, DuPont™ Hytrel® Black Coating, -3

- MADE IN U.S.A.

- Meets or exceeds SAE 100R14 specifications

- -65°F to 450°F (-54°C to 232°C) Continuous Service

- -100°F to 500°F (-73°C to 260°C) Intermittent Service

- Overbraided with 300 series stainless steel wire

- DuPont™ Hytrel® Black outer jacket / coating

- Compatible with Fragola Real Street (RS) and Racetronix TP-series reusable fittings

current production may vary from item image

Smooth bore Teflon hose has been the universal problem solver of industry for many decades. Through a process known as cold head extrusion, tetrafluoroethylene powder is transformed into a smooth tube of PTFE. Only the finest Dupont T62 is used to manufacture the best quality PTFE tubing in the industry. State-of-the-art quality control methods, meticulous attention to every foot of hose and proprietary processes unique to the industry make this PTFE hose product the very best in the world.

This hose is widely specified for an endless variety of applications including automotive, food processing, pharmaceutical, chemical and petrochemical. It can be found in factories, on trucks and buses, automobiles on and off road, in laboratories, in endless manufacturing situations; anywhere that the limitations of rubber, metal and synthetic hoses make PTFE hose the only solution.

DuPont™ Hytrel® Black outer jacket / coating combines the flexibility of rubber with the strength and processability of thermoplastics. Hytrel® thermoplastic elastomer resin can flex in multiple directions, cycle after cycle, long after rubber would break. A prime example is the Constant Velocity Joint (CVJ) boot, an automotive component that is subject to an average of 150,000 miles of pounding, and a wide range of temperatures. Hytrel® provides supperior abrasion and chemical / solvent / gas resistance and is easy to clean.

| Hose Size (In) |

I.D. (In) |

O.D. (In) |

Operating Pressure (PSI) |

Burst Pressure (PSI) |

Weight (lbs/ft) |

Bend Radius (In) |

SS Braid (Nonconductive) Item Code |

SS Black (Nonconductive) Item Code |

SS Clear (Nonconductive) Item Code |

SS Braid (Conductive) Item Code |

SS Black (Conductive) Item Code |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/16 | .1378 | .250 | 3000 | 12000 | .047 | 2 | TFT1167-03 | TFT1167-03B | TFT1167-03C | TFT1170-03 | - |

| 1/4 | 0.1875 | .312 | 3000 | 12000 | .077 | 2 | TFT1167-04 | TFT1167-04B | - | TFT1170-04 | - |

| 3/8 | 0.3281 | .445 | 2500 | 10000 | .110 | 4 | TFT1167-06 | - | - | TFT1170-06 | TFT1170-06B |

| 1/2 | .405 | .549 | 2000 | 8000 | .124 | 5.2 | TFT1167-08 | - | - | TFT1170-08 | TFT1170-08B |

| 5.8 | .500 | .648 | 1500 | 6000 | .154 | 6.5 | - | - | - | TFT1170-10 | TFT1170-10B |

| 3/4 | .625 | .775 | 1200 | 4800 | .170 | 7.7 | - | - | - | TFT1170-12 | TFT1170-12B |

| 1 | .875 | 1.030 | 1000 | 4000 | .273 | 8 | - | - | - | TFT1170-16 | - |